PLEASE NOTE THAT DUE TO SOME FRAUDULENT CUSTOMERS WILL REQUIRE CONFIRMATION OF YOUR IDENTITY OR WILL ACCEPT WIRE TRANSFERS

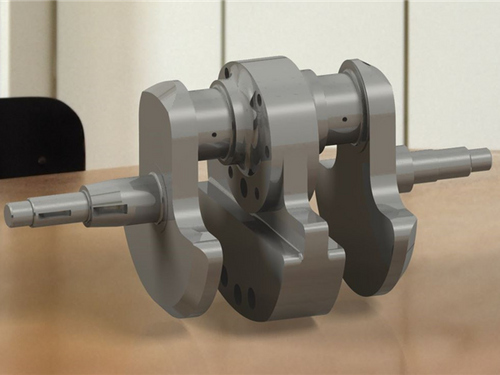

The three piece design of the Norton Commando crankshaft has been manufactured and used since the late 1980`s and it is now available to our customers but with the benefit of full CAD design and CNC manufacture. We start with premium Nickel Chromium Molybdenum Steel and then machine the engine crankshafts on our range of CNC machines before hardening & tempering to 60 tonnes UTS. The separate flywheel is manufactured from the same grade of steel and held together with high tensile studs & nuts. Obviously, the lighter the crank of a Norton Twin, the better the engine is, and with improved acceleration and braking. The 89mm stroke cranks are just over 20 pounds (9.1kg) which is the lightest that can be produced whilst achieving our desired balance factor of 75% for rigidly mounted engines. If you are planning to mount the engine in an "Isolastic" chassis, the balance factor needs to be reduced to 52% & this should be notified at the time of ordering. Due to the manufacturing process the dynamic balance is improved compared with standard cranks. This results as it relates to the balance factor assumes the use of stock rods & pistons. At the moment, 89mm and 93mm (for 1000cc engines) stroke cranks is available, but the range may expand in the future.

If desired, we can dynamically balance the crank to suit your exact piston and rod combination but this requires precise weights from you (or the actual components) and is subject to additional cost.

We do ship internationally and share our deep discounts with all of the major shipping services.